Engineering the Future of Machinery with Advanced Materials & Intelligent Sourcing

We supply custom-engineered metals and components, along with real-time sourcing solutions, driving innovation, productivity, and helping to create world-class manufacturing capabilities.

about us

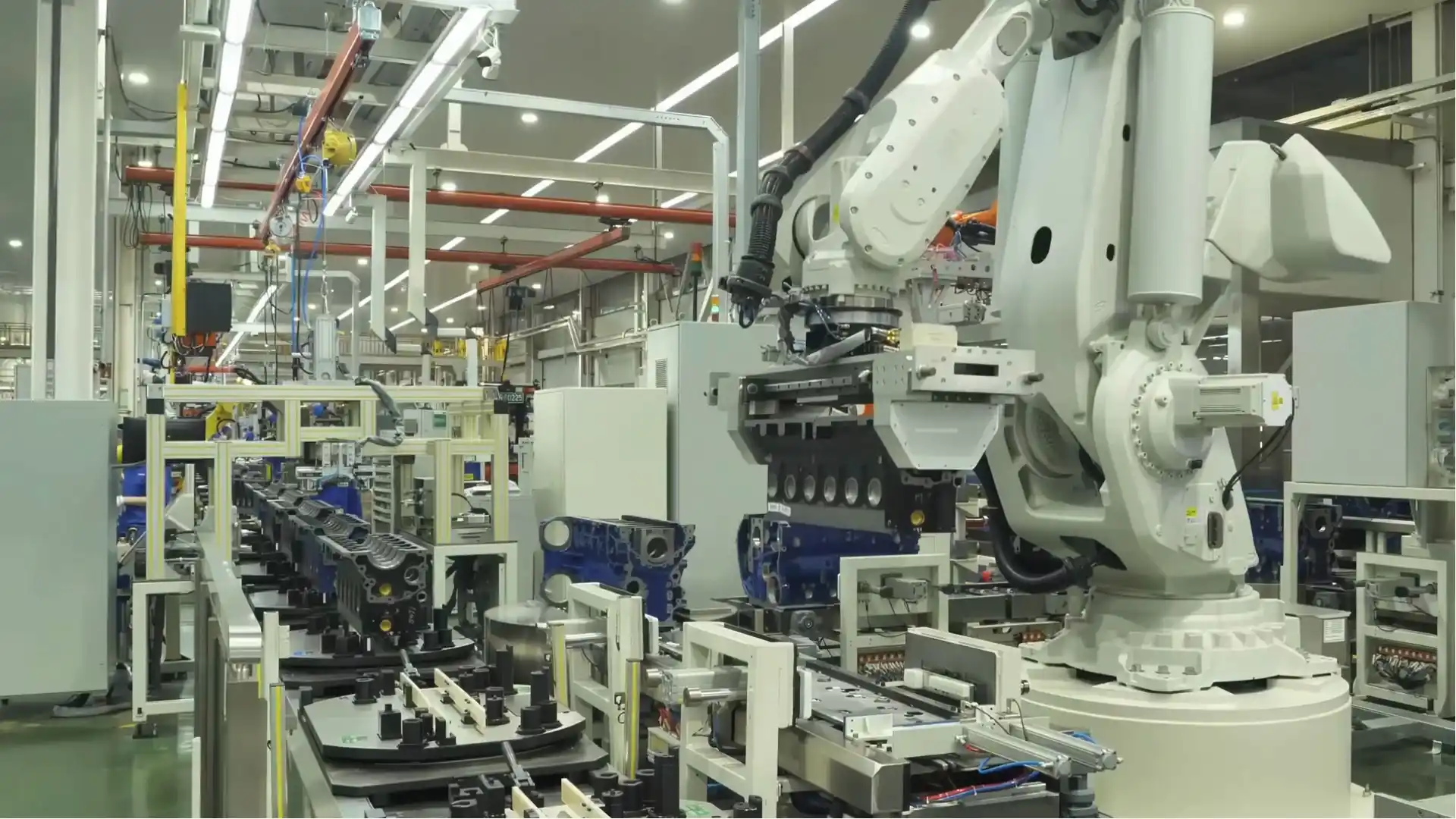

The machinery and equipment industry is central to global manufacturing, supporting the automotive, construction, energy, mining, automation, and industrial engineering sectors. From heavy machinery and production systems to precision tools and automated lines, the sector relies on high-strength metals, engineered components, and wear-resistant materials that ensure accuracy, durability, and long service life. As India advances its manufacturing capabilities, the demand for certified materials, consistent quality, and reliable supply continuity is rising. Automation, component indigenisation, and new-generation equipment are driving the reliance on precision materials and efficient sourcing.

Metalbook powers the machinery & equipment industry with high-quality metals, precision components, and engineered materials designed for high-performance manufacturing. From structural parts and assemblies to tooling alloys and wear-resistant alloys, we provide materials that enhance durability, productivity, and operational efficiency.

Our offerings

Project Execution

End-to-end solar project execution from planning to commissioning.

Project Financing

Structured financing options to accelerate solar project deployment.

Marketplace

One platform to source certified solar components from trusted manufacturers.

Customized Products

Tailor-made metal solutions engineered for specific industry and project requirements.

Why Metalbook

Pan India Supply Network

Verified OEM partnerships with certified products

Transparent pricing & procurement intelligence

Digital tracking & supply chain visibility

One Stop Solution

Quality assurance & compliance

Tailor-made financing solutions for you

What do we do

01

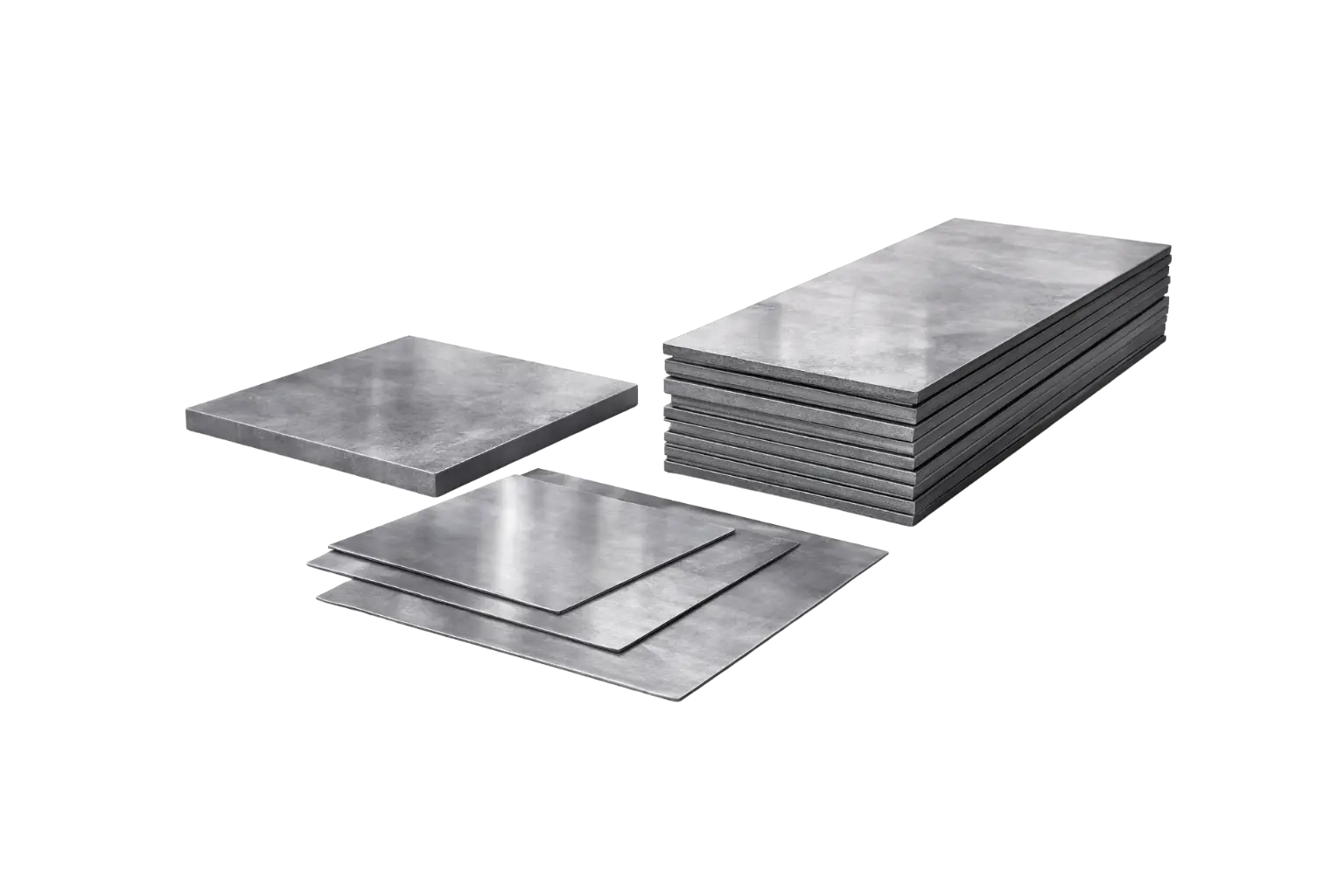

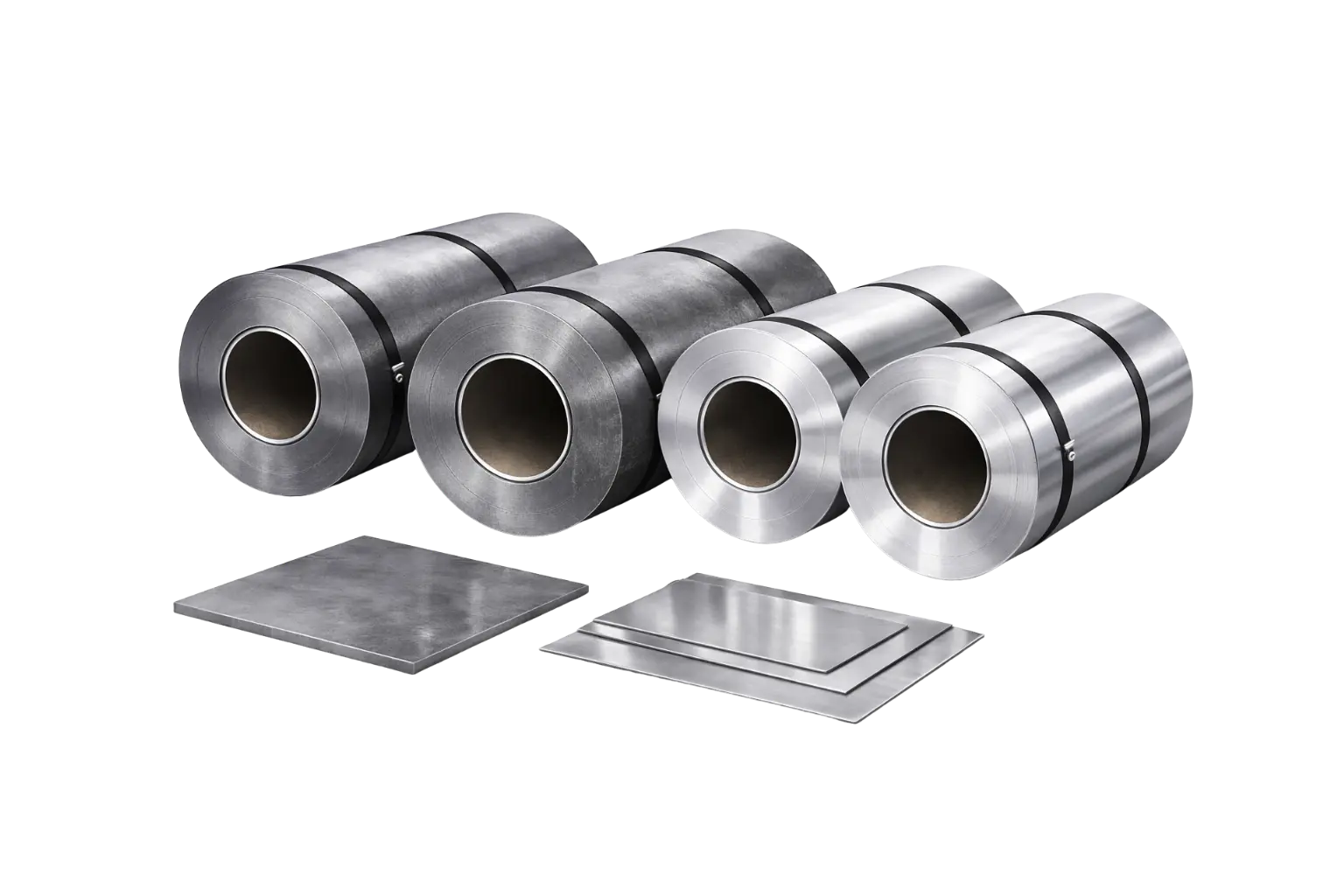

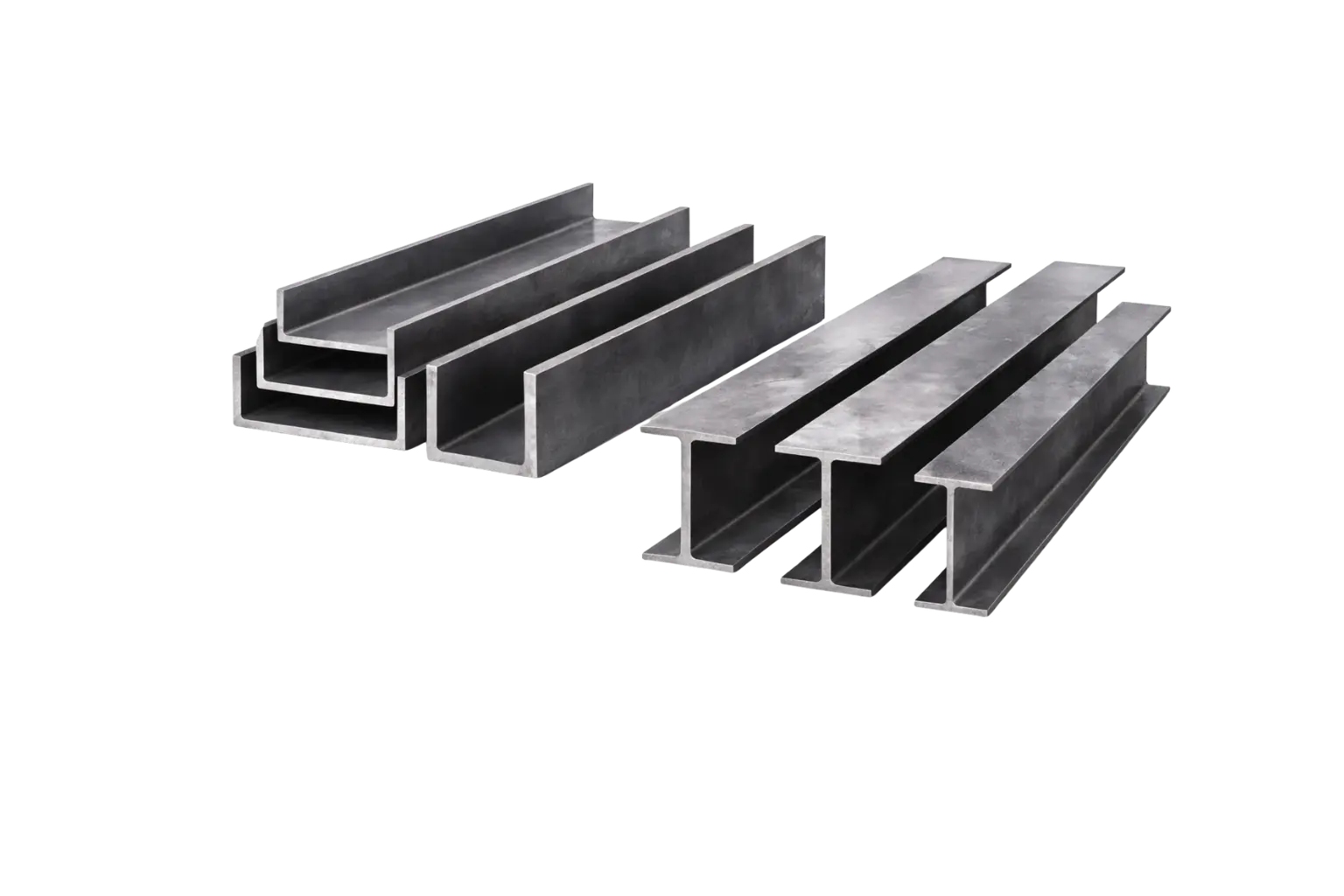

Supply High-Quality Raw Materials

We source essential raw materials from trusted manufacturers across India and globally. This includes steel plates, sheets, bars, beams, angles, channels, and coils. All materials come with proper mill test certificates and quality documentation, ensuring that your production processes start with reliable, factory-certified inputs.

02

Provide Metal Fabrication and Structural Elements

For more complex machinery assemblies, we supply ready-made fabricated components such as frames, supports, brackets, and structural parts. Our network of workshops specialises in producing these components according to precise specifications and drawings. We coordinate with these fabricators to produce components according to your drawings and specifications. and meet tight delivery schedules.

03

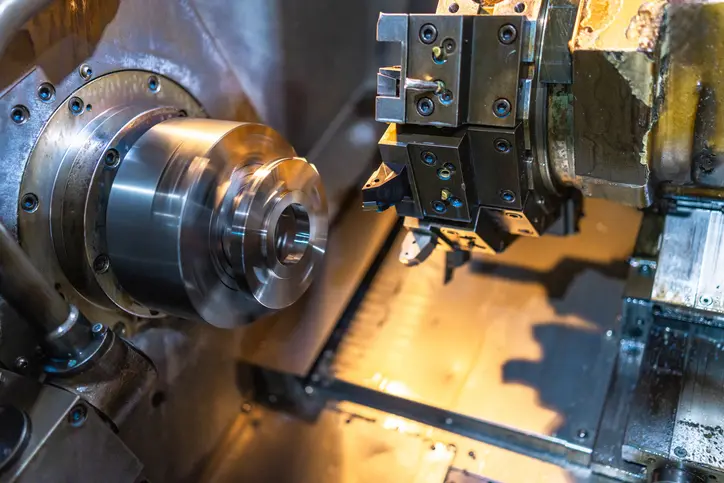

Metal Processing Services

Products

How Does Metalbook Help You

For Sellers

- Upload inventories such as structural steels, alloy steels, tool steels, plates, bars etc.

- Streamlined logistics, pickup and documentation to ensure proper dispatch.

- Faster movement to verified machinery OEMs, fabricators, and industrial manufacturers.

- Gain access to higher volume orders and recurring industrial demand.

For Manufacturers and Fabricators

- Receive consistent requirements, validated, quality verified, from suppliers.

- Search by type of Material using advanced Sourcing Filters (i.e., grade, thickness, hardness, tolerances, and shape).

- Reduce downtime/Increase Machine Utilisation through predictable sourcing.

For OEMs

Supply chain resilience through diversified domestic & global sourcing.

Quality assurance with complete traceability and documentation.

Lower sourcing risk through supplier verification and performance.

One-stop sourcing ecosystem for materials, components, and production-ready assemblies.

Get in Touch

Source materials faster through a digital, verified, and sustainable ecosystem.

Looking ahead?

Active Tenders in the machinery & equipment Industry

blogs

Application of Nickel alloys in Aerospace vs Automotive Industries

Nickel alloys are utilized in a variety of industries, which includes aerospace, automotive marine, chemical processing and electronics, due to their favorable attributes, such as corrosion resistance, elevated thermal stability and fabricability. Many advancements were identified in the article, such as Sanicro 625 in aerospace and Monel 400 in Automotive for high-corrosion or brake-system applications, and their importance for these industries to enhance operational capacity and safety in extreme operational conditions.

Mild Steel vs Hot Rolled Steel: Key Differences

Steel can seem like an easy material to understand. However, selecting from hot rolled steel or mild steel can vary significantly based on meaning related to impact on project. Each type of steel plate has its advantages, and mechanical properties, as well as method of fabrication must be understood to understand differences in order to make an informed decision on the right steel product. One of the biggest differences is strength and this makes knowing the differences important from a perspective of value in cost and applicability to save you time, effort, and money.

The Importance of Zinc Die Casting in Automotive Industry

Introduction to Zinc Die Casting Die casting is a process that forces molten zinc under very high pressure into steel molds called dies. It is a good method of metal casting due to zinc's properties that make it suitable to be used in various industrial and commercial applications. Zinc is a very useful material for die casting because it has a very low melting point, is strong, and offers corrosion resistance. Casting is a procedure mostly used by metal fabrication industries since it allows the fabrication of complicated metal parts with ease. Precision and speed are compelling reasons among other factors behind choosing the die casting method rather than other metal fabrication techniques. Zinc die casting often finds its application compared with Aluminium casting or Aluminium DIE CASTING, but zinc with its different properties has particular advantages in numerous applications.

Frequently asked Questions