Metal Supply for Automotive & Transportation Manufacturing

We connect OEMs, tier suppliers, and component manufacturers with quality metal suppliers. Get precision materials on time, at competitive prices.

about us

Metalbook is a digital marketplace for the automotive and transportation industry. We help vehicle manufacturers, component makers, and tier suppliers source metals from verified suppliers across India and globally. Our platform handles procurement, quality checks, fabrication, and delivery so you can focus on production. We work with over 1500 suppliers to ensure you get the right materials when you need them.

Our offerings

Project Execution

End-to-end solar project execution from planning to commissioning.

Project Financing

Structured financing options to accelerate solar project deployment.

Marketplace

One platform to source certified solar components from trusted manufacturers.

Customized Products

Tailor-made metal solutions engineered for specific industry and project requirements.

Why Metalbook

Pan India Supply Network

Verified OEM partnerships with certified products

Transparent pricing & procurement intelligence

Digital tracking & supply chain visibility

One Stop Solution

Quality assurance & compliance

Tailor-made financing solutions for you

What do we do

01

Supply Raw Materials

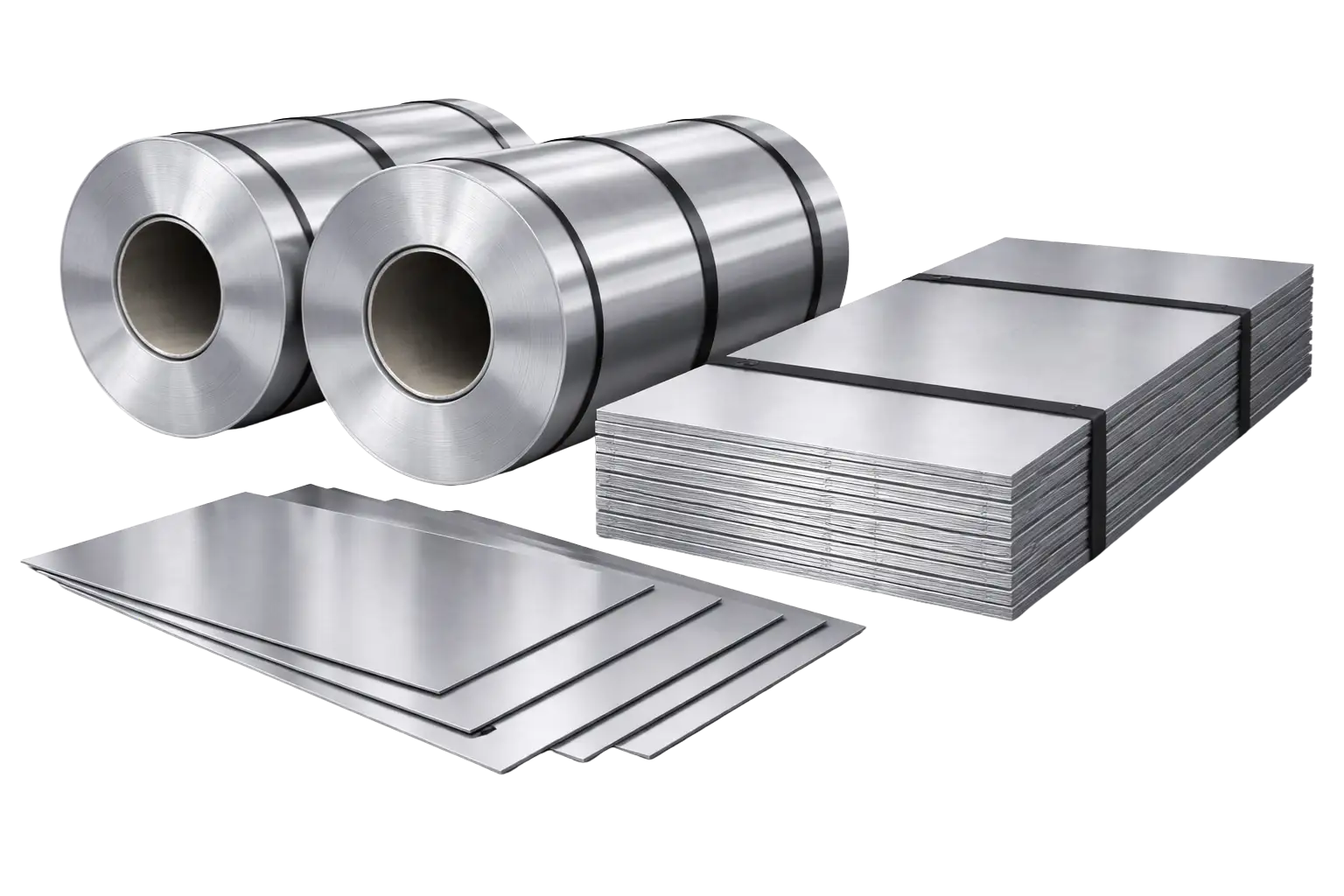

We source automotive-grade metals from manufacturers across India and globally. This includes high-strength steel sheets, aluminum alloys, stainless steel, copper strips, and specialty metals. All materials are supplied with proper mill test certificates and material certifications required for automotive applications. You can order through our platform, track your delivery, and manage multiple suppliers from one place. We work directly with steel mills and metal producers to get you competitive prices while meeting stringent automotive quality standards.

02

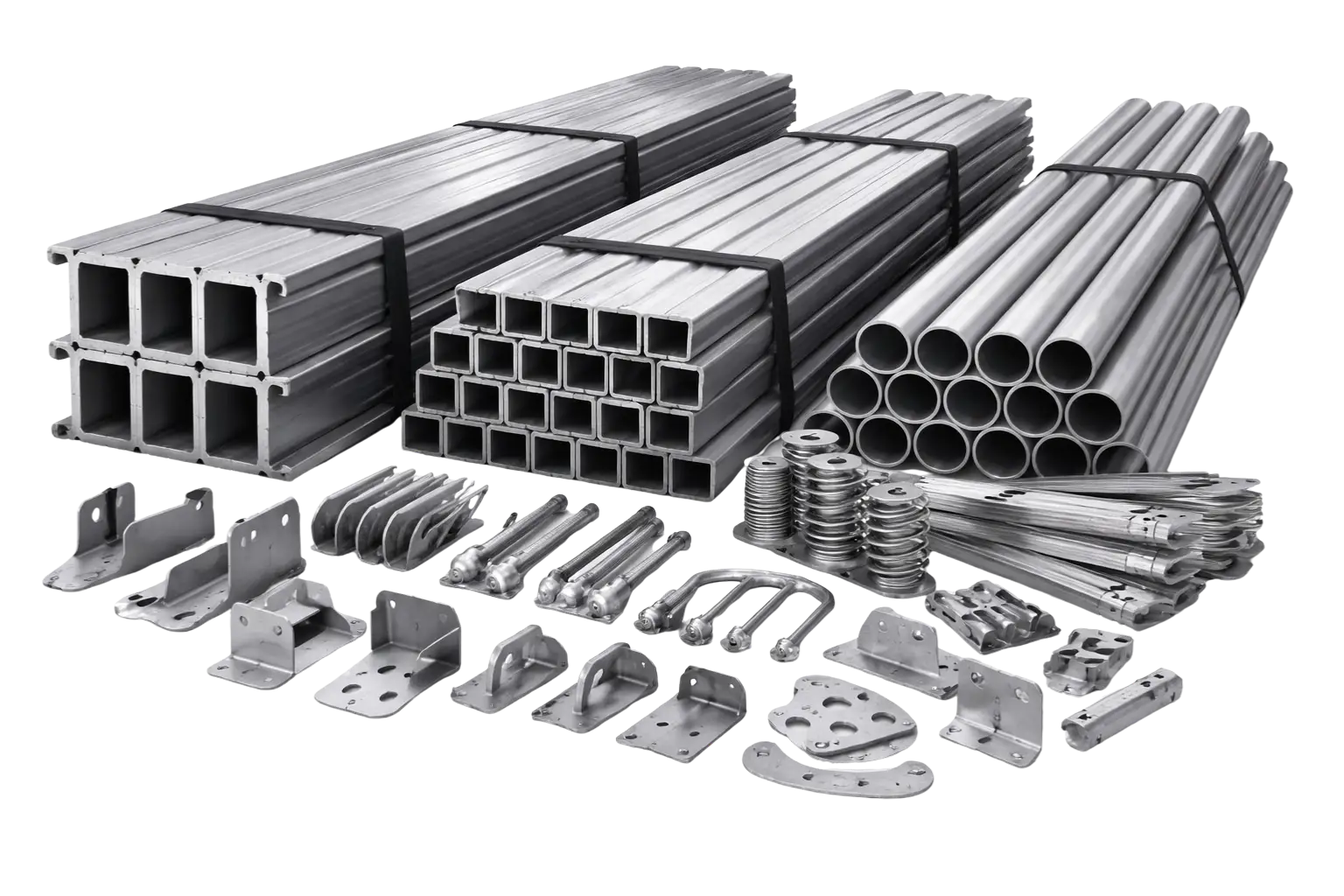

Provide Precision Components

Automotive manufacturing requires more than just raw materials. We supply precision-cut blanks, stamped components, machined parts, and fabricated assemblies. Our network includes processing partners who specialize in automotive components for body panels, chassis parts, engine components, brake systems, and exhaust assemblies. We coordinate with these manufacturers to produce parts according to your technical drawings and specifications. This reduces your inventory holding and ensures parts arrive production-ready.

03

Metal Processing Services

Products

How Does Metalbook Help You

For Sellers

- Upload inventories such as CR/HR coils, high-strength steel, aluminum sheets, stainless steel, and copper strips.

- Streamlined logistics, pickup and documentation to ensure proper dispatch to manufacturing facilities.

- Faster movement to verified automotive OEMs, tier suppliers, and component manufacturers.

- Gain access to high-volume orders and recurring production demand from auto industry.

For Manufacturers and Fabricators

- Receive consistent requirements, validated and quality verified, from automotive suppliers.

- Search by material specifications using advanced sourcing filters (grade, thickness, hardness, tensile strength, and coating).

- Reduce production downtime through predictable sourcing and just-in-time delivery.

- Increase machine utilization through steady material flow aligned with production schedules.

For OEMs

Supply chain resilience through diversified domestic and global sourcing networks.

Quality assurance with complete traceability, material certifications, and PPAP documentation.

Lower sourcing risk through supplier verification and performance tracking.

One-stop sourcing ecosystem for raw materials, precision components, and production-ready assemblies.

Get in Touch

Source materials faster through a digital, verified, and sustainable ecosystem.

Looking ahead?

Active Tenders in the automobiles Industry

blogs

How the Renewable Industry Benefits from Non-Ferrous Metals

Today, strengthened government policies, higher developments in technology, and investment opportunities are leading to rapid expansion of renewable energy in India. Solar is the fastest-growing sector, with an annual growth rate of 25 to 30 percent, while keeping in mind the ambitious target of 500 GW renewable energy capacity by 2035 and net-zero by 2047. PLI schemes, Basic Customs Duty on imports, and the Make in India program are some initiatives through which domestic manufacturing is being boosted, cutting down reliance on foreign components. Industry leaders are picturing the transformation in renewable growth in India brought by innovative solar solutions that include high-efficiency solar modules with energy-efficient solar inverters and smart grid integration. Additionally, renewable energy has helped the electricity sector in emission reduction. Investment inflows from global and domestic investors are being attracted by the strong policy option combined with the ever-increasing approach toward sustainability. This momentum will fast-track India's transition to clean energy while also positioning India as a global entity in renewable technology and manufacturing. By creating a Renewable ecosystem that is resilient and self-reliant, the country is laying the foundations for a future that is sustainable and energy secure.

Application of Nickel alloys in Aerospace vs Automotive Industries

Nickel alloys are utilized in a variety of industries, which includes aerospace, automotive marine, chemical processing and electronics, due to their favorable attributes, such as corrosion resistance, elevated thermal stability and fabricability. Many advancements were identified in the article, such as Sanicro 625 in aerospace and Monel 400 in Automotive for high-corrosion or brake-system applications, and their importance for these industries to enhance operational capacity and safety in extreme operational conditions.

Mild Steel vs Hot Rolled Steel: Key Differences

Steel can seem like an easy material to understand. However, selecting from hot rolled steel or mild steel can vary significantly based on meaning related to impact on project. Each type of steel plate has its advantages, and mechanical properties, as well as method of fabrication must be understood to understand differences in order to make an informed decision on the right steel product. One of the biggest differences is strength and this makes knowing the differences important from a perspective of value in cost and applicability to save you time, effort, and money.

Frequently asked Questions